Brewster windows

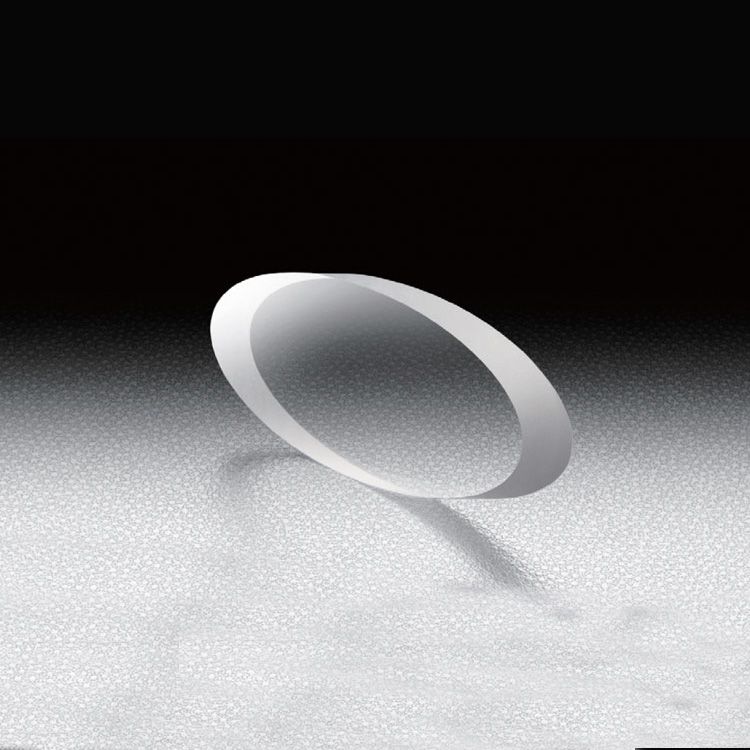

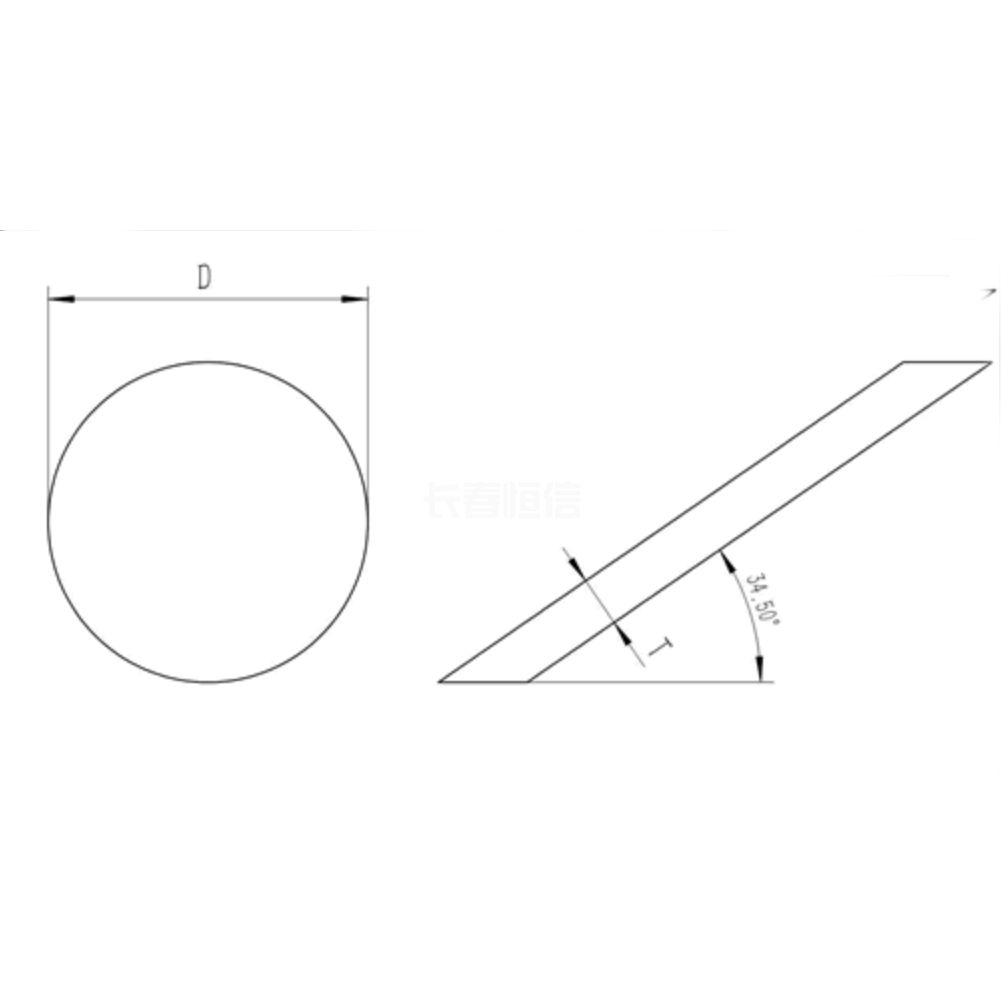

A Brewster window is an uncoated substrate that is positioned at Brewster's angle within a laser, instead of external mirrors. This substrate acts as a polarizer, such that the p-polarized light enters and exits the window without reflection losses, while the s-polarized light is reflected.

Brewster windows are fabricated using UV fused silica that does not have laser-induced fluorescence, which makes it well-suited for applications that use ultraviolet to near infrared light.

With the introduction of a Brewster window in the laser path, the laser light hits the window at Brewster's angle, thereby producing a completely polarized light.

A typical example of a Brewster's window is a helium-neon laser, provided with a sealed glass tube, and an external resonator with mirrors. The gas mixture is separated from ambient air by the glass windows. While considering the small output coupler transmission and small gain, the losses at these interfaces are below 1% per pass.

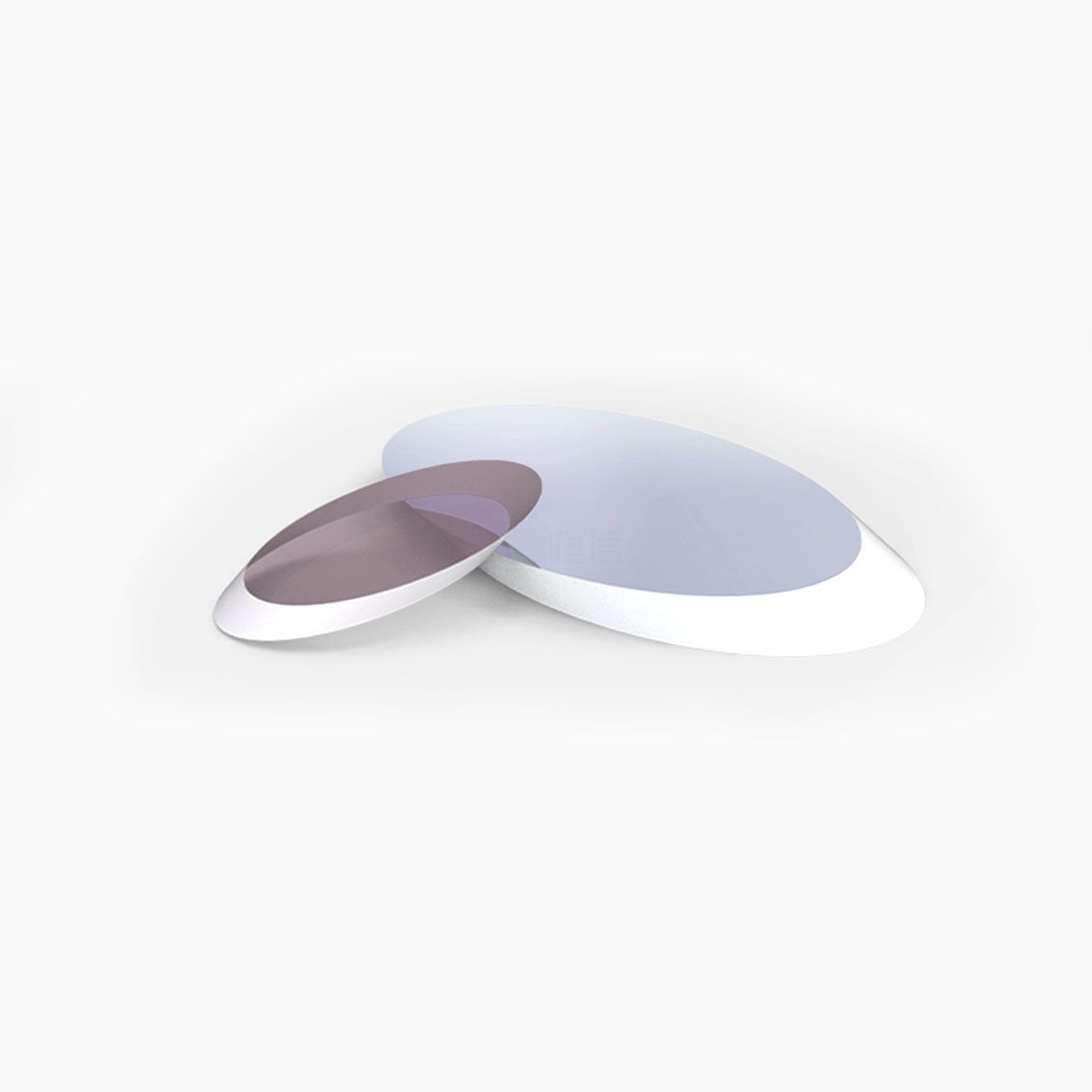

In general, the reflectivity of any uncoated glass plate at normal incidence is several percent. However, with the use of an anti-reflection coating, the percentage can be reduced to as low as 0.2%. Brewster windows can have over 10 times lower losses, comparatively.

Moreover, any residual reflection in the Brewster window will leave the resonator, rather than causing interference effects. The polarization of laser emission is usually forced along the p-direction, due to the difference in loss between s and p polarization. In most of the lasers, the polarization direction is determined by this effect.

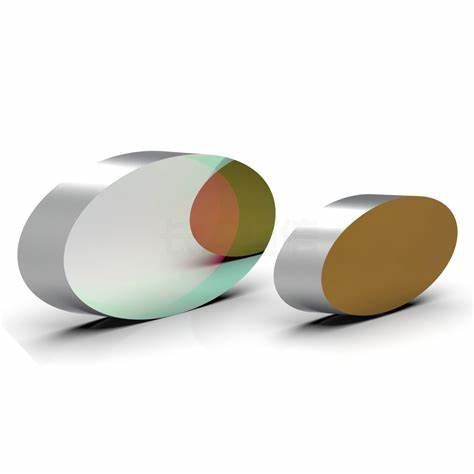

| Material | BK7 and Fused silica typically, Visible optical glass, Infrared optical glass. | |||

| Tolerances | Low precision | Standard Precision | High precision | |

| Glass Quality | nd | ±0.001 | ±0.0005 | Melt controlled |

| vd | ±0.8% | ±0.3% | Melt controlled | |

| Dimension Tolerance (mm) | ±0.10 | ±0.05 | +0.01/-0.01 | |

| Angle Tolerance (θ1) | 3 minutes | 1 minutes | 10 second | |

| Angle Tolerance (θ2) | 3 minutes | 1 minutes | 10 second | |

| Scratch-Dig | 60-40 | 40-20 | 20-10 | |

| Wave front Distortion at 632.8nm | λ/2 per 25mm | λ/10per 25mm | λ/20 per 25mm | |

| Clear Aperture | 80% | 90% | 95% | |

| Bevel | 0.3±0.10mmx45°or upon requirement | 0.1±0.10mmx45° | ||

| Coating | Coating may be available by custom order | |||